Year Round

Air Conditioned Respirator For

A Comfortable Workplace

Invented, Patented, & Made in the USA

Providing Clean, Comfortable Air Supply in All Conditions. Breath Easy. Work Harder. Stay Safe.

Introducing The Tennessee Chill Box for the Hard Working Professional

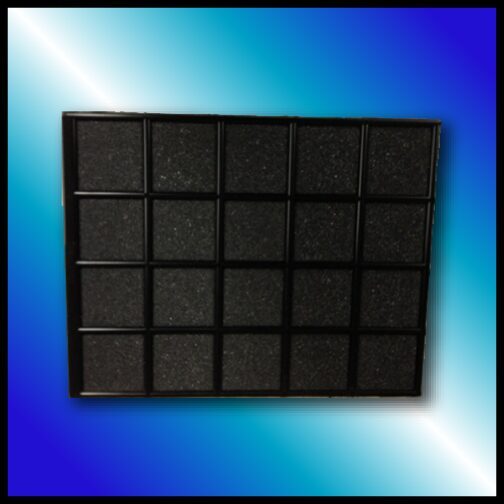

NEW! HEPA & ULPA /Activated Carbon Filter for the Chill Box PROTECT THE AIR YOU BREATHE

NEW Product Update! The CHILL BOX Waterproof Drawstring Bag for MASKS and HOODS!

High CFM Year-Round Fresh Air Systems!

NOW WITH COOL BREEZE SUIT AND DUAL AIRLINE -TO KEEP YOUR BODY AS COOL AS YOUR HEAD!

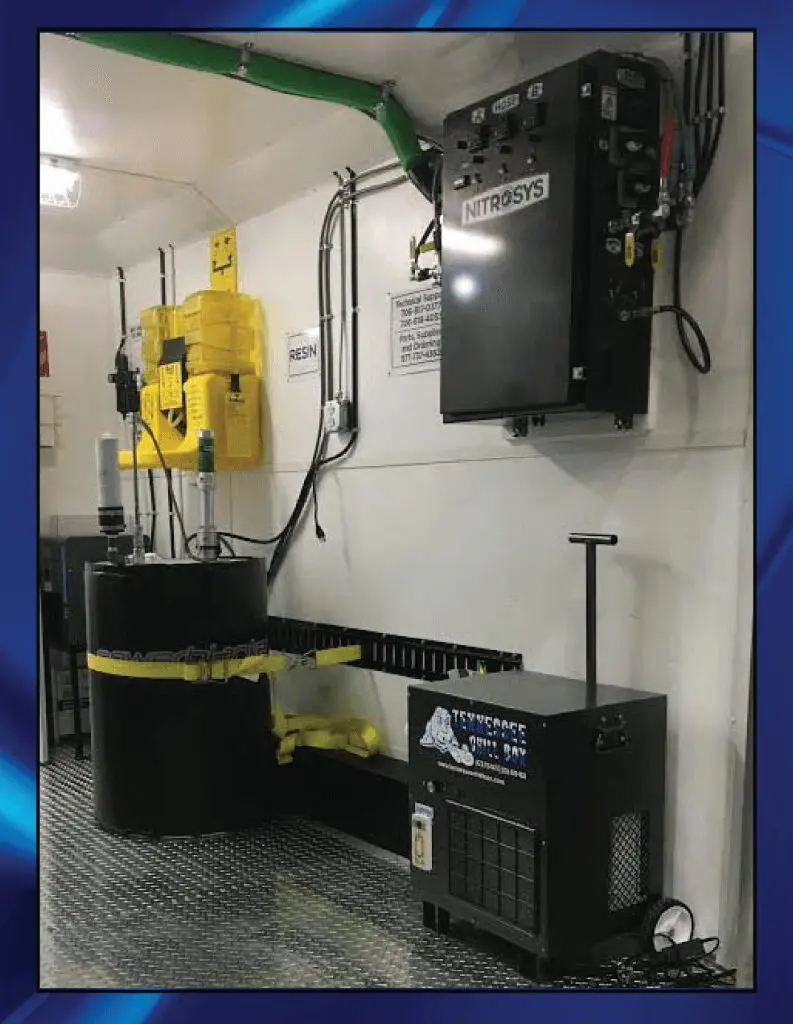

The Tennessee Chill Box 8000 (CB8000) is an Air-Conditioned Respirator, Fresh Air Supply System, which provides comfortable, safe breathing air for industry users who require a fresh air supply system, with the advantages of air-conditioned air.

It can maximize productivity and eliminate the possibility of heatstroke, heat exhaustion, dehydration, nausea, and cramps for your workers.

The CB8000 Improves the worker’s safety and comfort, reducing their frequency and duration of breaks on the job.

The Tennessee Chill Box is Made in the USA and can be shipped anywhere throughout the USA, Hawaii, Canada, Mexico, and internationally.

Shop Now

Please read article below...

Published Sept. 21, 2021

Jennifer Goodman Lead Editor

Dive Brief;

- The White House announced yesterday that OSHA plans to create a federal standard to help prevent a growing and largely under-reported hazard on construction sites: heat-related illness.

- The advance notice of proposed rulemaking, set to be released next month, is the first step in the process for developing a workplace heat standard. It will initiate a comment period allowing OSHA to gather diverse perspectives and technical expertise on topics including heat stress thresholds, heat acclimatization planning, exposure monitoring and strategies to protect workers.

- Thousands of workers are sickened each year by workplace heat exposure.

Extreme heat kills more Americans than any other climate-related hazard, and workers’ rights groups and public health officials have long pushed for a federal worker safety rule, according to Politico.

Labor Secretary Marty Walsh said in the release that increasingly hot outdoor temperatures from climate change are adding to the issue.

"Amid changing climate, the growing frequency and intensity of extreme heat events is increasing the dangers workers face, especially for workers of color who disproportionately work in essential jobs in tough conditions," he said.

Hot weather safety can be a challenge in traditionally cooler areas like the Pacific Northwest, Cameron Samuel, assistant safety director at Western Specialty Contractors, told Construction Dive.

"It is more difficult to protect workers in regions not used to extreme heat spikes, especially when they occur early in the summer season," he said. Especially early in the summer, crews are not used to the heat, which means their tolerance is low and they are more susceptible to heat illness.

Other steps

OSHA is also implementing an enforcement initiative on heat-related hazards and developing a National Emphasis Program on heat inspections. .

The OSHA initiative applies to indoor and outdoor worksites in general industry, construction, agriculture and maritime where potential heat-related hazards exist. On days when a recognized heat temperature can result in increased risks of heat-related illnesses, OSHA will increase enforcement efforts.

Employers are encouraged to implement intervention methods.

OSHA will also be advised to expand the scope of inspections to address heat-related hazards where worksite conditions or other evidence indicates these hazards may be present.

OSHA Developing Standards for Hot Working Conditions

Excessively hot weather is responsible for killing more Americans than any other weather conditions, and the health and safety organizations think that the number is much higher than reported. Hot weather is becoming more extreme; therefore, workers and their employers are facing increasing challenges to remedy workplace health and safety issues. The real danger comes from workers facing hotter weather than they are used to. There is not enough time for them to acclimate to the heat slowly. This means that their tolerance for working in the heat is low, so they are more likely to succumb to heat-related illnesses.

What is OSHA’s Plan?

The OSAH heat-related initiative will entail implementing an enforcement of worker “temperature safety” ranges as well as heat inspections in the workplace. It is also developing an educational program to bring about more awareness of heat injury and illness. This will culminate into a Best Practices standard to protect all workers. Inspections will occur when the heat index is above 80 degrees F. The initiative applies to both indoor and outdoor workers.

What is Causing Extreme Heat Conditions?

Climate change is the main cause of extreme heat conditions. Across the country, people are dealing with more extreme weather, most of which they are unaccustomed to. This means that they are often ill prepared to deal with these extreme weather changes. We are seeing more flooding, hurricanes, heavy rains, drought, extreme cold and hotter weather in areas that didn’t used to experience such extremes. According to weather experts, these extreme conditions are predicted to become worse over time. Therefore, climate change has become a worker safety concern.

How Have Some State Dealt with Extreme Weather Conditions?

Some states on the West Coast have implemented a Heat Illness Prevention Program, some of which was initiated in 2021. Oregon, for example, has requirements for employers to have designated shade areas, maintain available fresh drinking water, and make sure that employees are educated about heat-related illnesses and how to deal with them.

What Can be Done to Ensure Worker Safety?

Workers that spend their workdays on roof tops, in attics, crawl spaces, and in other confined and uninsulated spaces are finding it more challenging than ever before to get the job done. Time is money in most industries. Instead of slowing down the work, some companies have opted to provide their workers with an air-conditioned respirator and/or and air-conditioned suit. The Tennessee Chill Box has long been a resource for combatting extreme heat conditions. Workers who use air-conditioned protective equipment can stay alert, have no risk of heat-related illness, and can work just as long on the job as if they normally would.

For more information on the Tennessee Chill Box air-conditioned protective equipment, contact them at:

CONTRACTOR OF THE YEAR WINNERS

2020

Matt Mader

2021

Jennifer Edwards

2022

2022 Runner Up Winner For Spray Foam Magazine And The Winner Of The Tennessee Chill Box System

2023

2023 Runner Up Winner for Spray Foam Magazine and The Winner of The Tennessee Chill Box System

PROVIDING THE RESPIRATOR INDUSTRY SINCE 2005…

Our Year-Round Fresh Air/Air-Conditioned Respirator Supply Systems meet or exceed CFM requirements that are required by Industry Standards.

When the question is safety and comfort, the CB8000 is your answer! The CB8000 is not only for the HOT summer months but also provides continuous Year-Round Fresh Air for industry users!

CHECK OUT OUR PODCAST

Mission Statement

Tennessee Chill Box LLC is the inventor and fabricator of Air-Conditioned Fresh Air Supply Systems for respiratory protection. We believe that there is an intrinsic value, personal and financial reward in producing products and services that offer customers more value than they expect to receive. Those of us at TCB, succeed because our customers succeed, with a time-tested product and excellent customer service and support.

In short, we are a robust company that adapts to the ups and downs in individual industries so our customers can depend on us, to be there when they need us.

Remembering where we came from, knowing somehow, someway, there had to be a safer, better, more comfortable, affordable respirator for those in the trades. We recall using specific respiratory systems that seemed to make breathable fresh air worse.

We are grateful for the unconditional support from the various industries, their leaders, and skilled workers for insisting on our units.

FABRICATION

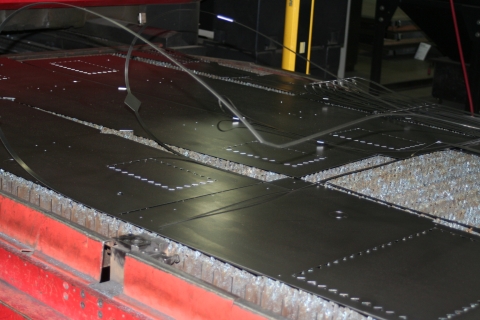

The Tennessee Chill Box’s metal fabricating facility, Metalworking Solutions in Chattanooga, TN, utilizes state of the art laser cutting precision for the CB8000. Their high-speed laser-cutting technology provides an on-point precision laser cut that houses the components for the Chill Box. Comprising from flat drawings produced by Tennessee Chill Box, this operation allows for the correct precision cuts and measurements for Tennessee Chill Box’s manufactured parts to fit properly during manufacturing and assembly processes. The laser-cutting machine’s advanced features such as flying optics, linear drives, and beam adjustments result in tight tolerance parts with the cleanest edge cuts for the CB8000.

The quality steel used in the outer shell provides long-lasting strength and durability, increasing manufacturing efficiency, and part quality. The ultimate design for the CB8000 system is unique.

A Turret punch press offers the exact placement of vents and outlets for special assembly requirements and quality assurance for the product.

The welding process is distinctive, placing invisible welds to add individuality to the look of the CB8000 systems exterior. The welders are experienced in freehand welding of fabricated sheet metal parts. The Chill Box outer metal housing is now ready for a completed final inspection before it is delivered to another location for the special powder coating.

Creating a high-quality, textured, durable finish that allows for maximum protection for the Tennessee Chill Box. Powder coating protects the CB8000 as it is more resistant to impact, moisture, chemicals, and UV rays, along with extreme weather conditions.

INDUSTRY When safety and comfort is the issue… CB8000 is your answer!

If you desire comfortable, safe breathing air, that has the benefits of air conditioning, the Tennessee Chill Box CB8000 is the answer to your needs. Anyone requiring a respiratory breathing apparatus while working on the job will benefit immensely from the CB8000 system.

Eliminate the possibility of heatstroke, heat exhaustion, dehydration, nausea, and cramps for workers in the industry. Improve the worker’s safety and comfort, reducing their frequency and duration of breaks on the job. Maximize your productivity year-round as well as extreme temperatures with the CB8000 High CFM Respirator Supply System. The system supplies breathable fresh air that is air-conditioned when you need it.

Our non-compressed blower-driven, ambient fresh air /air-conditioned supply system does not use compressed air, thus eliminating the need for air compressors and repair parts, as well as the possibility of harmful vapors and oil mist. This Air-Conditioned Fresh Air Supply System utilizes Grade “D” breathable air and is virtually maintenance-free with the exception of a washable front panel filter. No expensive calibration needed or expensive testing is required, unlike most compressed systems on the market today!

The respirator supply system features a dual man system that is used in conjunction with the proper air hose lines and accessories provided by the Tennessee Chill Box, ensuring proper CFM output.

The CB8000 could well be the most comprehensive system in the industry today for Respirator systems, providing year-round air-conditioned fresh air to respiratory users.

The CB8000 can be used with hoods, respiratory ratchet shield, or full-faced mask. Only Tennessee Chill Box breathing tubes, airlines, and connections are to be used with the Fresh Air /Air-Conditioned System. The Single or Dual man system can utilize up to 200 ft of air hose for each airline. When you receive your CB8000, it is a complete self-contained fresh air supply system, including all airlines, hoods, or masks, breathing tubes, and connections.